Nitro-Lift is a vertically integrated oil and gas service provider who has become the Exclusive distributor of nanoActiv in the lower 48 United States.

Nitro-Lift Technologies

FREQUENTLY ASKED QUESTIONS

Based in Houston, Texas, Nissan Chemical America Corporation is a division of Nissan Chemical Corporation founded in Japan in 1887. A forerunner in chemical innovations for more than 130 years, Nissan Chemical has been perfecting nanoparticle technology since 1951, making it one of the first companies in the world to produce highly surface-modified colloidal particles for industrial applications.

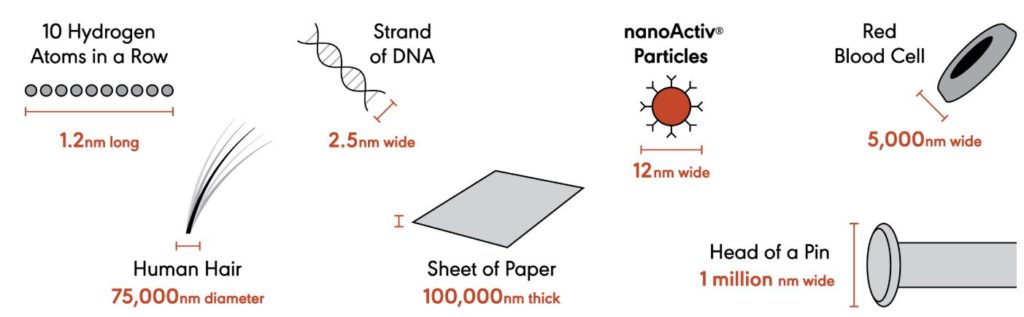

Nanotechnology refers mainly to engineered particles that range from 1–100 nanometers in size. A nanometer (nm) is one-billionth of a meter, equivalent to one-millionth of a millimeter, and one-thousandth of a micron. For comparison, a piece of copy paper is 100 microns thick—in nanometers this is 100,000nm thick. A human hair is about 75 microns in diameter or 75,000nm. Also, a red blood cell is 5 microns wide, this is 5,000nm.

A nanoActiv® nanoparticle is a surface treated silicon dioxide particle.

Nissan Chemical developed a nanoparticle fluid named nanoActiv®, to penetrate micro pores in hydrocarbon rich formations. nanoActiv® particles are 12 to 15 nanometers in diameter and increases hydrocarbon production once thought to be unrecoverable by traditional stimulation methods, thus improving the RECOVERY FACTOR of the well.

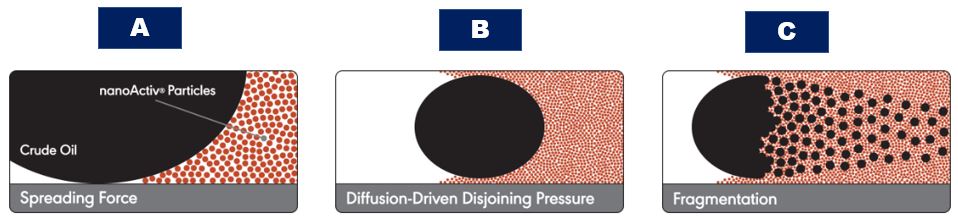

A.) The nanoActiv® solution is injected into an existing well along with nitrogen, carbon dioxide, or water as a carrier.

B.) As nanoActiv® moves into the wellbore the particles infiltrate the pore spaces, begin to dislodge and disjoint the hydrocarbons, breaking the hydrocarbons into smaller droplets by oscillating in a continuous motion (Brownian motion).

C.) The hydrocarbons then flow into the wellbore, while the nano particles continue to work deeper into the reservoir.

Frac Hit Mitigation, EOR/IOR, Remediation, and New Completions.

Frac-Hit Mitigation- $100,000 to $500,000+

EOR/IOR Horizontals- $100,000 to $250,000+

EOR/IOR Verticals- $10,000 to $50,000

New Completions- $200,000 to $500,000+

It varies, but generally 6 to 12 hours for vertical wells and 24 to 60 hours for horizontal wells.

We’re unsure, but we have seen lasting positive impacts (3.0x), on wells treated 2 years ago during the initial R&D phase.

They can be depending on the connectivity of the wells. Customers are encouraged to watch the volumes of the wells on the same pad or surrounding the treated well(s).

Yes.

Yes.

Yes, but we will need to do a compatibility test beyond 200,000 TDS.

Go to RecoverMoreOil.com and fill out the “Well Data Submission Form” form.

Be prepared to collect and send oil and water samples to be tested.

Yes, go to RecoverMoreOil.com and visit our Case Studies page or contact a Nitro-Lift sales representative.

Yes.

None, unless your well has a packer. The packer will have to be unseated.

YES! See below or you can listen to the webcast hosted by World Oil.

A Femtometer is one-millionth of a nanometer. When used appropriately, this size scale is used to describe subatomic particles. For example, a proton is about 1 femtometer in size.

Subatomic particles don’t typically exist outside of atoms in nature. It is not appropriate to use femtometers to describe normal inorganic or organic molecules—these are typically angstroms, nanometers, or micrometers in size.

“Femtotechnology”, for now, has no practical application and is considered hypothetical by futuristic scientists and engineers.

Sodium metasilicate is Na₂SiO₃, a form of waterglass. The molecules of this chemical are of the normal angstrom or nanometer scale. Also known in the dissolved form as waterglass—it is a reactive chemical used for sealing pores and causing colloidal particles to sediment out of solution. The most common use in oilfield chemistry is in drilling fluids as a borehole stabilizer—where the pore sealing properties are useful. When exposed to variable pH, dissolved alkali earth metals (like calcium or dissolved salts of calcium) or dissolved organic materials, Na₂SiO₃ is prone to polymerization. This is the main reason it is used as a borehole stabilizer and even as a zone sealant/water shutoff agent.

Fumed silica, also known a pyrogenic silica, is produced by burning SiCl4 (silicon tetrachloride) in an oxygen-enriched environment. The SiO2 smoke formed is amorphous silica which has been fused together to form much larger agglomerated particles, sometimes in the micron to millimeter size range. Due to its three-dimensional structure, fumed silica has a strong thickening effect and has the ability to modify the rheology of various fluids. Colloidal silica, in contrast, contains mostly separate individually dispersed particles that have not been fused together and can therefore be in the nanometer size range.

Materials that are not prone to polymerization are safe to use downhole. Sodium silicates are reactive and prone to polymerization—this is exactly what makes them useful in many other commercial applications. This tendency makes them dangerous to use downhole. These materials are an excellent choice for plugging and sealing pores in sandstone, and carbonate lithologies—not for removing more oil and gas from your well. Some major oilfield companies have patented the use of sodium silicate/waterglass type chemistry for stopping, reducing, or modifying pathways for fluid flow.

Surfactants are nanometer and angstrom scale organic molecules that have a water-loving side and an oil-loving side of the molecule. This dual property is what makes them good at making oily type molecules more soluble in water. The oil-loving side of a surfactant molecule can associate with an oily molecule (crude oil) and the water-loving side of the surfactant molecule makes the whole thing dissolve in water better. This dual property also allows surfactants to alter wettability of certain rock formations.

Nanotechnology consistently outperforms traditional surfactant technology because of the physical/mechanical mechanisms involved. Nanoparticles are often also naturally attracted to the oil-water interface. nanoActiv® takes advantage of this tendency and employs diffusion-driven Brownian motion to wedge hydrocarbons from rock surfaces. Surfactants simply attempt to coax hydrocarbons out using a chemical effect. nanoActiv® reaches deep and uses a brute-force physical effect to drive oil from the formation.

Due to the way they are designed (hydrophilic), nanoActiv® particles might show up in the produced water, but not in the oil. The quantities likely to return are very small, based on field data. As such, there is no impact on oil specifications or on refineries.

Due to their size (too small), it is very challenging to trace nanoActiv® particles. Some research is underway to try to discover where the particles go.

No. Normal PPE is enough. The particles are simply silicon dioxide with a patent-pending special surface coating (to make them withstand the harsh environment inside a well).

Each application needs to be designed specifically for the reservoir/fluids and various other parameters of a particular well. Different types require different volumes and concentrations of nanoActiv®. After providing the data required from the operator, NCA will advise on do-ability and viability for the suggested application, from both technical and economic aspects.

Yes. Frac’ing is only one application out of many, but is where the positive impact of using nanoActiv® has been demonstrated in hundreds of wells. nanoActiv® can be used in already frac’ed wells, depleted wells, and in many other cases.

Acid can impact the particles’ coating. Hence, it has to be spent before nanoActiv® is pumped. We generally pump water spacers before and after pumping nanoActiv® to make sure nanoActiv® does not come in contact with acid.

We have seen many instances with increased oil and gas production. Intuitively, this would also make sense, as lighter density fluids should be easier to recover. We have recently pumped in gas-only wells and are waiting for more data.

There are two versions of nanoActiv® HRT. The higher temperature version can withstand up to 180° C (350° F).

Naturally fractured reservoir, oil-wet, tight, and low permeability along with fractures away from aquifers are the ideal scenarios. In all cases, candidate wells will be discussed and screened with involvement of both parties (operator and technology provider).