Dislodge and Fragment Friction Reducers and Prevent Shut-In Damage with nanoActiv®

Well Remediation

nanoActiv® Remediation treatments are low-cost treatments to clean damaged, low producing wells.

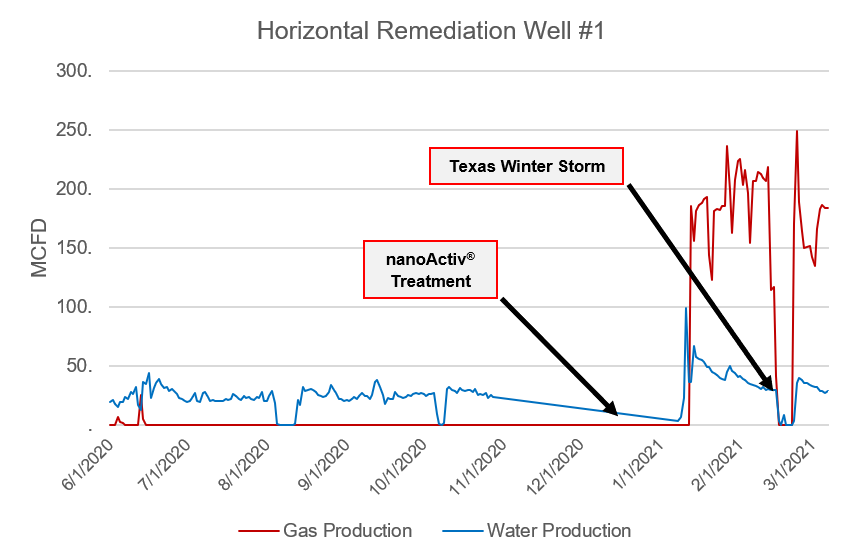

This well was drilled in 2010 with a 4,500′ lateral and had an initial production of 4,000 Mcfd. By May of 2020, the well was shut in. In December 2020, the well was treated with nanoActiv® Remediation Treatment and allowed to soak for 10 days. After 2 months, the well is producing 200 Mcfd and is still trending upward.

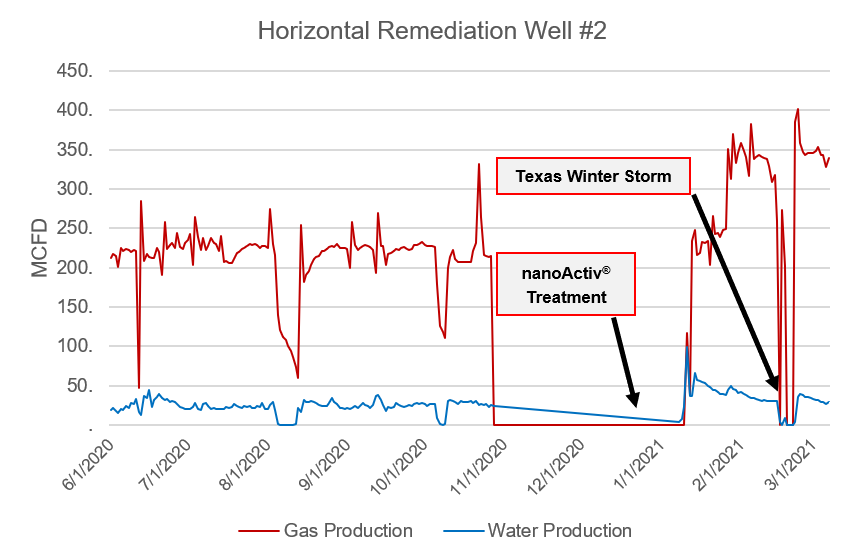

The well was drilled in 2010 with a 4,300′ lateral and had an initial production of 5,500 Mcfd. By October 2020, the well had declined to approximately 210 Mcfd. In December 2020, the well was treated with a nanoActiv® Remediation Treatment and allowed to soak for 10 days. After 2 months the well is producing 350 Mcfd and still trending upward.

Based on the producer’s economics, the treatments paid back in < 60 days.

Remediation Summary

Purpose: Remediation treatments provide well production “boosts” by repairing formation damage caused by polyacrylamide, fines migration, iron oxide, etc. They “clear the runway” for long-lasting nanoActiv® HnP treatments.

Cost: $15,000-$25,000 for horizontal wells. $7,500-$10,000 for vertical wells.

Pump Time: ~2-4 hours per well

nanoActiv® has proven to remediate skin damage and break through clogged pores caused by polyacrylamides, paraffin, iron sulfides, etc… See how nanoActiv® breaks apart iron sulfide in the video to the right.

Iron Sulfide Fragmentation

Remediation Tech Tips

nanoActiv® Creating Interface on Walls of Dead End Pore.

DISLODGE FRICTION REDUCERS & PORE THROAT PLUGGING WITH nanoActiv®

A friction reducer (FR) is a high-molecular-weight, anionic, and water-soluble

copolymer approximately 1,000 nanometers in size (1 micrometer). FRs in micropores less than 1,000 nm can plug the pore throats and pores, reducing oil and gas permeability and causing skin damage. As a result, well production rates suffer and ultimate recovery declines.